Binotto designs and manufactures an extensive range of underbody telescopic cylinders, specifically desgined to be light in weight, compact and are predominantly for special side tipping applications.

Manufacture from a complete range of tube dimensions, from 1 stage up to 9 stages, the comprehensive Binotto underbody telescopic cylinder catalogue ensures the most appropriate cylinder for each tipping body application and its intended use.

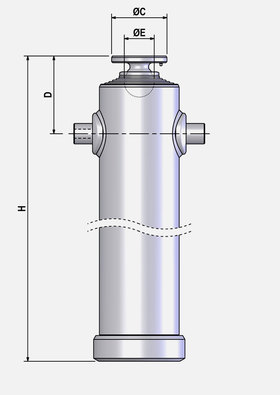

| DESCRIPTION | STAGES | STROKE [mm] | ØC [mm] | D [mm] | H [mm] | ØE [mm] | Download |

|---|---|---|---|---|---|---|---|

| B SC 8/1620/238 | 8 | 1620 | 130 | 215 | 360 | 60 | |

| B SC 8/1780/238 | 8 | 1780 | 130 | 215 | 424 | 60 | |

| B SC 8/1940/238 | 8 | 1940 | 130 | 215 | 444 | 60 | |

| B SC 8/2100/238 | 8 | 2100 | 130 | 215 | 464 | 60 | |

| B SC 8/2260/238 | 8 | 2260 | 130 | 215 | 484 | 60 | |

| B SC 8/2420/238 | 8 | 2420 | 130 | 215 | 504 | 60 | |

| B SC 8/2740/238 | 8 | 2740 | 130 | 215 | 544 | 60 | |

| B SC 8/3200/238 | 8 | 3200 | 130 | 215 | 601 | 60 | |

| B SC 8/1940/269 | 8 | 1940 | 130 | 220 | 454 | 68 | |

| B SC 8/2260/269 | 8 | 2260 | 130 | 220 | 494 | 68 | |

| B SC 8/2420/269 | 8 | 2420 | 130 | 220 | 514 | 68 |

BSC series is safe strong and compact. In fact it is short height and specifically designed for those vehicles with limited mounting space: this type of underbody telescopic cylinders fits lower trunnions and top reversed ball attachment.

In case of very limited space for installation, shorter version is also available upon request (BSSC series)

BSC cylinders can be used both for dump trucks and for tipping trailers and semitrailers.

Thanks to its special height, BSC series turns out to be very useful and suitable as a side tipper cylinder, especially for long side tipping semitrailers

Binotto top quality manufacturing processes and advanced technologies, combined with the special internal design of the cylinders, ensure these products are strong, safe and reliable.

Lower trunnions are made in special alloy steel to maximize their main mechanical properties.

Moreover they are quenched and tempered. These special heat treatments increase strength and ductility as revealed after tensile and impact test (up to 50% increased performances).

Additional induction hardening process on the trunnions surface increases the superficial hardness (up to 300%) for a better resistance to wear and tear.

The top ball is also induction hardened.

Made by one-pieces seamless steel, with “contact faces” stop-limits directly machined on the tubes, Binotto underbody cylinders are the obvious choice for those operators who are looking for a safe and robust tipping gear.

Machining accuracy and high technology manufacturing processes combined with proven experience and success around the world in the most arduous environments ensure Binotto underbody cylinders unrivalled quality, reliability and performance.