Strong, stable, fast: high pressure solution with Binotto A DWR twin underbody rams is proven worldwide to be unbeatable product, providing operators with maximum safety and reliable performances.

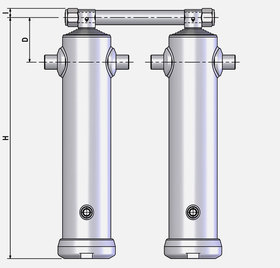

Double A DWR series consists in a twin ram tipping cylinder application with lower trunnions and top eye: the 2 cylinders are fixed together by a bespoke pin in order to work simultaneously as a single piece.

Easy fitting into the chassis is ensured by using special cradles available for each and every ram diameter.

As standard for all Binotto dump truck hoist cylinder, open and closed single lower brackets are also available for alternative fittings.

Special upper bracket will facilitate installation and attachment of the cylinders to the bottom of the tipper body.

| DESCRIPTION | STAGES | STROKE [mm] | D [mm] | H [mm] | I [mm] | WP [mm] | Download |

|---|---|---|---|---|---|---|---|

| A DWR 4-1220-130 - D.150 | 4 | 1220 | 149 | 472 | 32 | 250 | |

| A DWR 4-1600-130 - D.150 | 4 | 1600 | 149 | 572 | 32 | 250 | |

| A DWR 4-1780-130 - D.150 | 4 | 1780 | 149 | 622 | 32 | 250 | |

| A DWR 4-1940-130 - D.150 | 4 | 1940 | 149 | 672 | 32 | 250 | |

| A DWR 4-1780-149 - D.150 | 4 | 1780 | 149 | 631 | 32 | 250 | |

| A DWR 4-1940-149 - D.150 | 4 | 1940 | 149 | 681 | 32 | 250 | |

| A DWR 4-2420-149 - D.150 | 4 | 2420 | 149 | 831 | 32 | 250 | |

| A DWR 5-2425-168 - D.155 | 5 | 2425 | 153 | 686 | 32 | 250 | |

| A DWR 5-2825-168 - D.155 | 5 | 2825 | 153 | 786 | 32 | 250 | |

| A DWR 5-3225-168 - D.155 | 5 | 3225 | 153 | 886 | 32 | 250 |

Double A DWR series features standard Binotto solid design and construction: made by one-pieces seamless steel, with “contact faces” stop-limits directly machined on the tubes, Binotto twin ram tipping cylinders are the natural choice for those operators who are looking for a safe and robust tipping gear.

Machining accuracy and high technology manufacturing processes combined with proven experience and success around the world in the most arduous environments ensure Binotto underbody cylinders unrivaled quality, reliability and high performances.

Lower trunnions are made in special alloy steel to maximize their main mechanical properties.

Moreover they are quenched and tempered. These special heat treatments increase strength and ductility as revealed after our tensile and impact tests (up to 50% increased performances).

Additional induction hardening process on the trunnions surface increases the superficial hardness (up to 300%) for a better resistance to wear and tear.

This solution of dump truck hoist cylinder is dedicated to the rear tipping application only and it is also suitable for trailers and semitrailers.

Special cradle is designed for each diameter series in order to facilitate the installation within the chassis and avoid to design and fabricate additional items.

Upper bracket is also optionally available for easy fitting of the twin cylinders to the bottom of the tipping body.

Our dump truck twin cylinders can be installed within the most type of truck chassis worldwide.

In order to easily fit even to narrow chassis, it is possible to replace the special cradle with standard brackets for underbody cylinders. Both closed and open versions are available.